Custom Metal Facade Panels — Precise & Fast

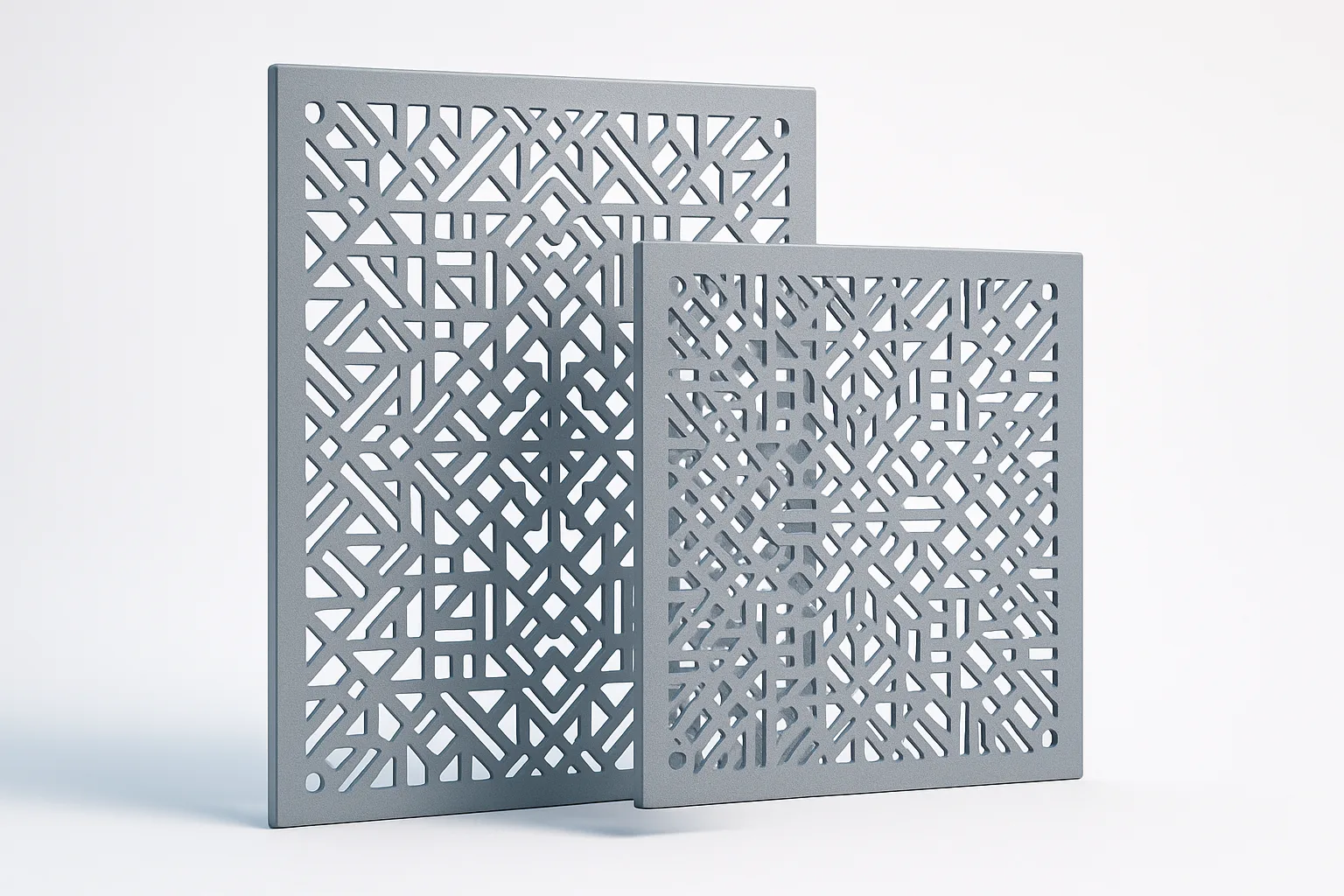

Laser-cut metal facade panels for architectural buildings. Steel, aluminum, stainless steel with durable outdoor powder coating lasting decades.

What are metal facade panels?

Metal facade panels are decorative sheets mounted on building exteriors, creating architectural accents and protecting walls from weather. Laser cutting enables perforated or solid decorative patterns.

Current trends favor laser-cut panels with geometric, leaf, or wave patterns — combining aesthetics with natural light and air circulation through the facade.

Technical Specifications

Manufacturing Process

Outdoor powder coating (polyester/PVDF)

Surface protection packaging

Recommended Materials

Aluminum 5052 is the most popular for facade panels due to its lightweight and corrosion resistance. SS400 with PVDF coating is an economical solution. SUS 304 for premium projects.

Industry Applications

Frequently Asked Questions

How long does outdoor powder coating last on facade panels?

Polyester powder coating lasts 10–15 years outdoors. PVDF (fluoropolymer) coating lasts 20–30 years with no fading, excellent UV resistance — ideal for premium projects.

What is the maximum size for facade panels?

Maximum cutting size is 3000×1500mm. Larger panels can be joined using a sub-frame system. Common thickness: 1.5–2.0mm for aluminum, 1.0–1.5mm for steel.