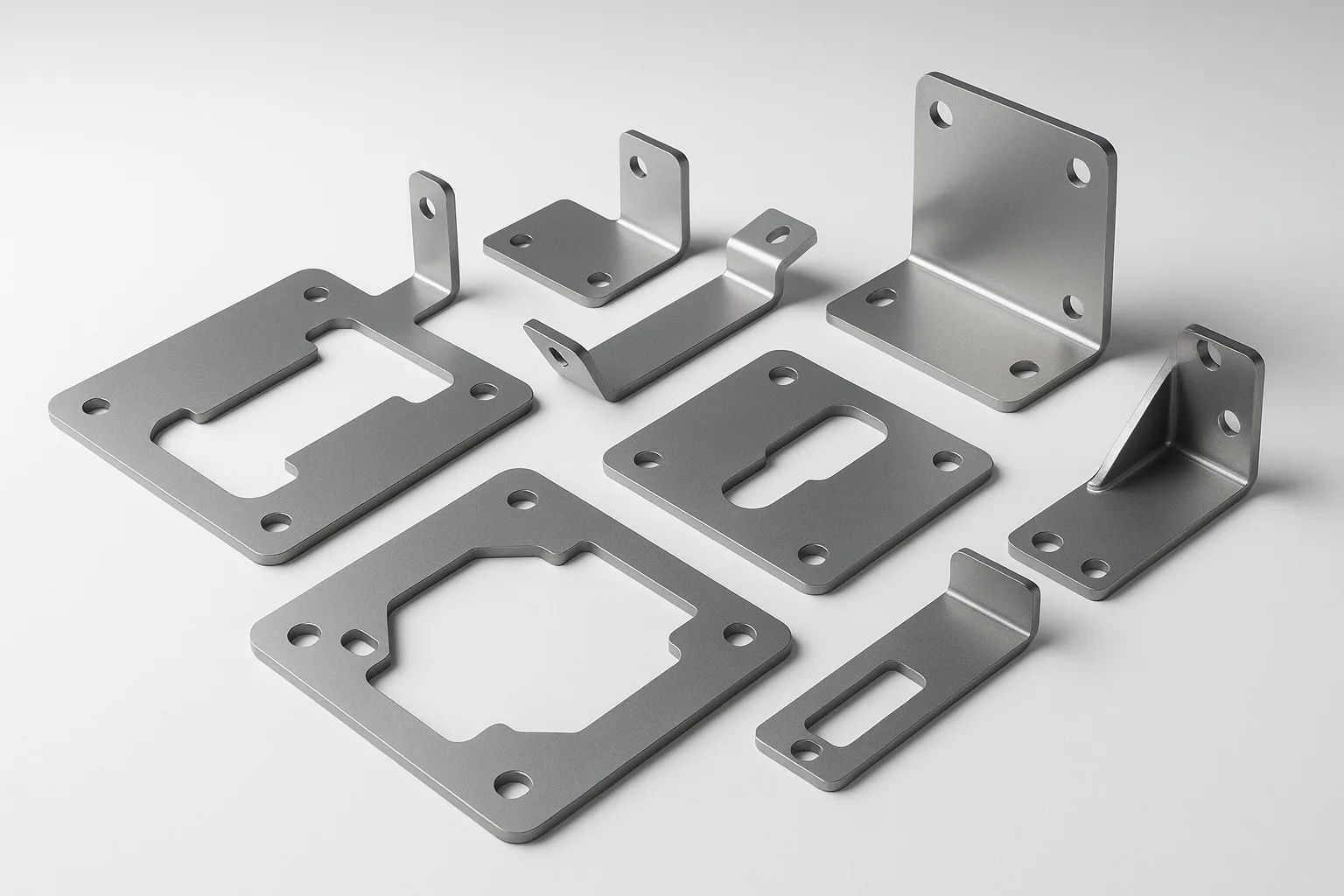

Custom Machine Parts Fabrication — Precise & Fast

Precision machine components from CAD drawings: base plates, flanges, partitions, guide rails. Fiber laser cutting with ±0.1mm tolerance on all materials.

What are machine parts?

Machine parts are sheet metal components used in machinery assembly: base plates, flanges, partitions, guide rails, guards and hundreds of other part types.

Machine part fabrication requires tight tolerances and consistency across batches. Laser cutting enables complex parts without tooling — saving costs for small batches and prototypes.

Technical Specifications

Manufacturing Process

Secondary operations: bending, drilling, tapping, deburring

Tolerance inspection and packaging

Recommended Materials

SS400 for structural parts, SUS 304 for corrosive environments, Aluminum 6061 when lightweight and heat dissipation matter. SGCC for parts needing coating.

Industry Applications

Frequently Asked Questions

Can you fabricate parts from 3D files?

Yes. We accept STEP, IGES, SolidWorks and Inventor files. Our engineering team will unfold 3D to 2D flat patterns for laser cutting.

What tolerance can laser cutting achieve?

Fiber laser tolerance: ±0.1mm for steel up to 6mm, ±0.2mm for 6–12mm steel. Bending tolerance: ±0.1mm. Superior to plasma or oxy-fuel cutting.