Military Equipment Parts Fabrication — Heavy-Duty Precision

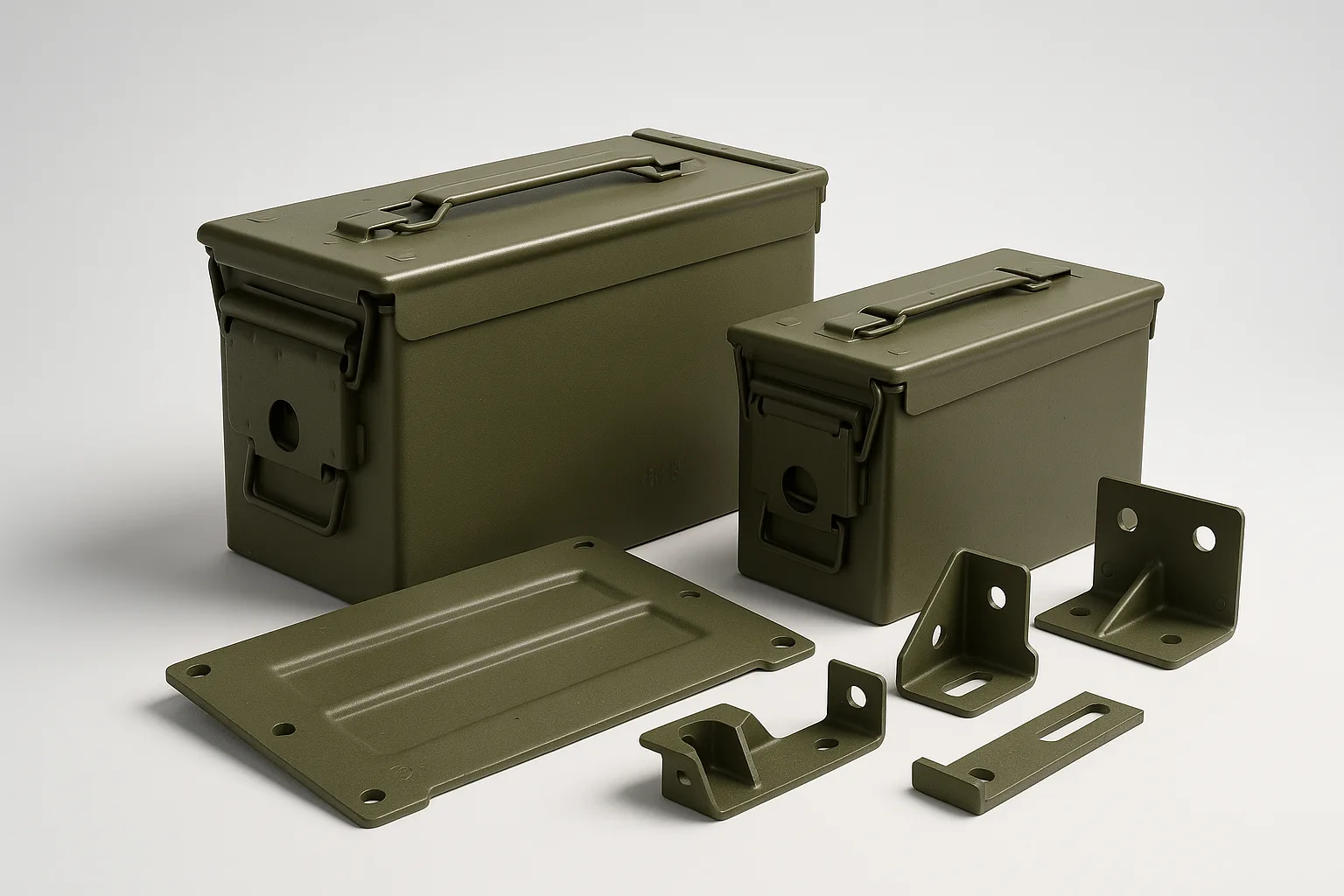

Military-grade sheet metal components including storage boxes, equipment brackets, panel assemblies and protective housings. Heavy-gauge steel, tight tolerances, durable surface treatment.

What are military equipment parts?

Military equipment parts encompass a wide range of sheet metal components used in defense applications — ammunition storage boxes, vehicle mounting brackets, communication equipment housings, armor panel assemblies and field equipment frames.

These parts require heavy-gauge materials (2.0–6.0mm), tight dimensional tolerances, and durable surface treatments to withstand harsh field conditions. Quality standards are stringent with full traceability required.

Technical Specifications

Manufacturing Process

Recommended Materials

SS400 mild steel is the standard for military equipment parts due to high strength and weldability. Aluminum 6061 for lightweight vehicle accessories. SUS 304 for corrosion-critical applications.

Industry Applications

Frequently Asked Questions

Can you fabricate to military specifications?

Yes. We fabricate to customer-supplied military specifications with full dimensional inspection reports and material certificates. ISO 9001 quality management ensures consistent output.

What thickness range for military parts?

Our laser cutting handles up to 20mm mild steel and 12mm stainless. CNC bending handles up to 6mm. For thicker plates, we combine laser cutting with welded assembly.