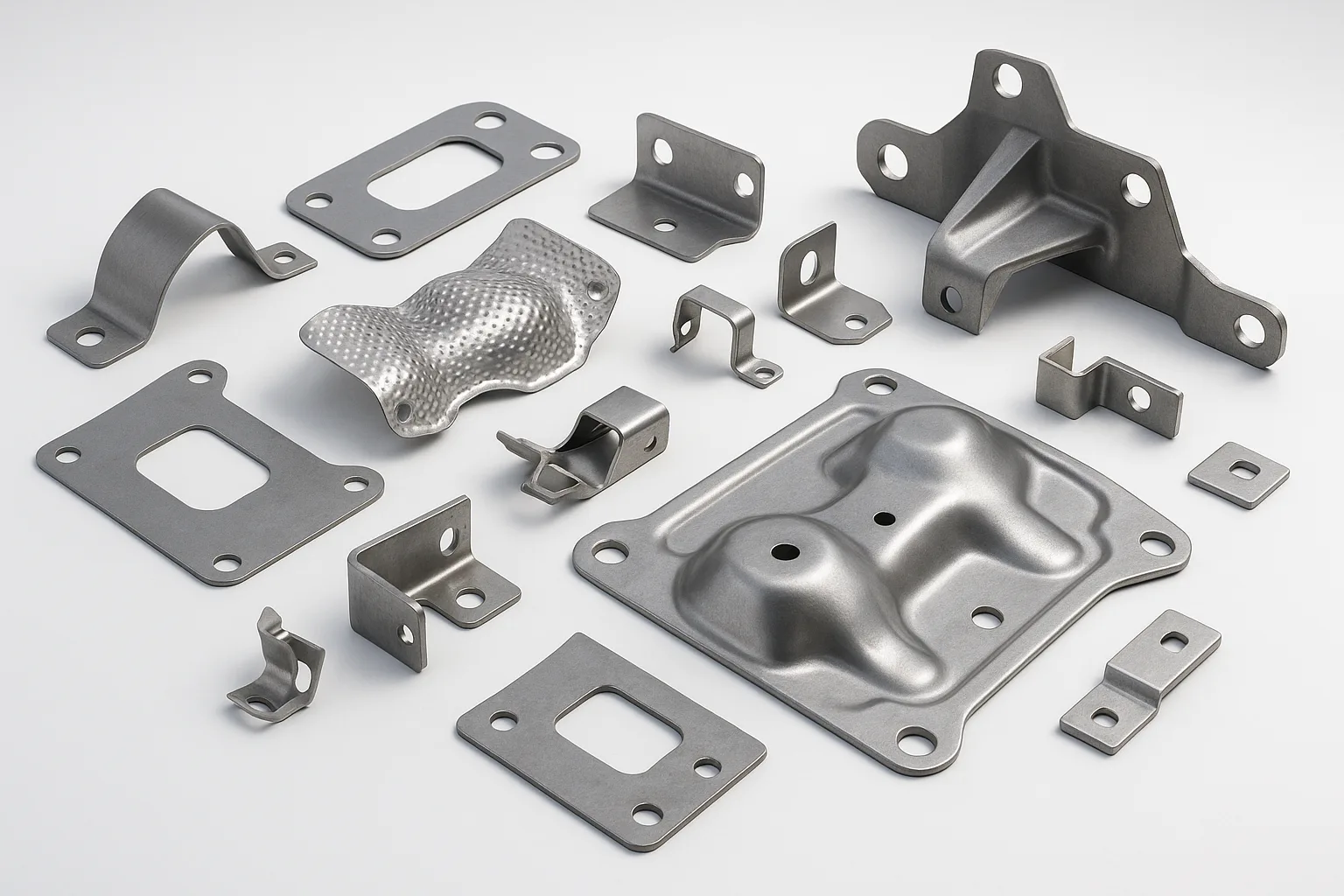

Custom Automotive Parts — Precise, OEM-Grade

Sheet metal components for automotive and motorcycle: brackets, panels, reinforcements, hinges. Precision laser cut, suitable for prototyping and production runs.

What are automotive sheet metal parts?

Automotive sheet metal parts include mounting brackets, reinforcement gussets, cover panels, door hinges — components stamped or cut from 0.8–3.0mm steel sheet. Tight tolerances required for OEM assembly fit.

Common materials: SS400 mild steel, SGCC galvanized (corrosion resistant), aluminum 5052 (lightweight). Surface treatments include electro-galvanizing, ED coating or powder coating per OEM specs.

Technical Specifications

Manufacturing Process

Surface treatment and dimensional inspection

Recommended Materials

SS400 mild steel and SGCC galvanized are most common for automotive parts. Aluminum 5052 for lightweight components. Stainless SUS 304 for exhaust or decorative trim.

Industry Applications

Frequently Asked Questions

Do you accept small-batch prototype orders?

Yes. We accept from 1-piece prototypes to production runs of 10,000+. Laser cutting is ideal for both prototyping and small-to-medium batch production.

How long does automotive parts fabrication take?

Prototypes: 3–5 days. Small batch (<500 pieces): 7–10 days. Large batch: 15–25 days depending on quantity and complexity.