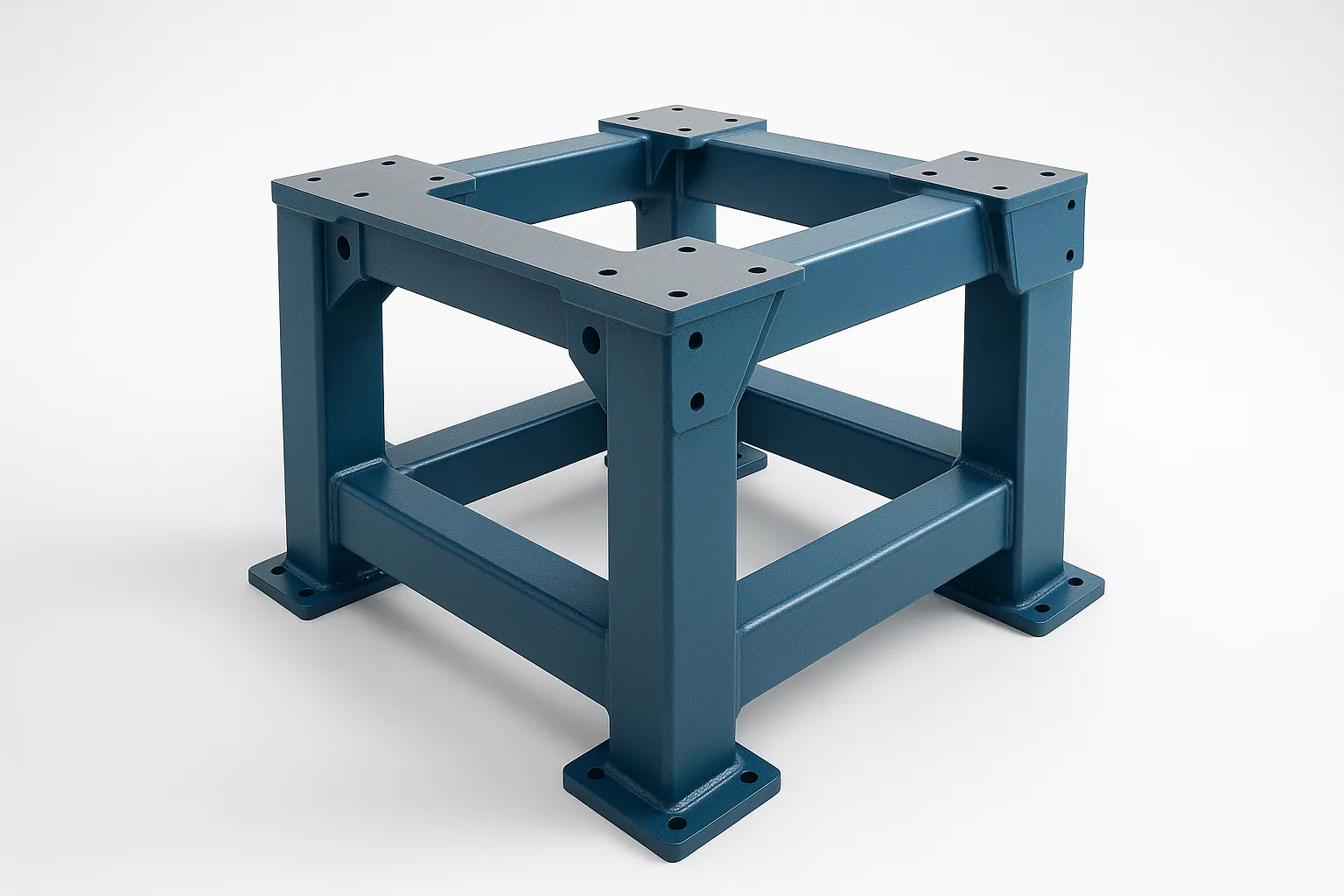

Custom Machine Frames — Strong & Precise

Machine frames and industrial equipment structures from sheet steel and structural tubing. Laser cut, bent, welded to drawings. Guaranteed load capacity, flatness and assembly tolerance.

What is a machine frame?

A machine frame is the primary load-bearing structure of equipment — supporting all mechanisms, motors and drive systems. Frames must ensure rigidity, vibration resistance and precise assembly tolerance for mounting points.

Industrial machine frames are made from SS400 mild steel 3–10mm, MIG/TIG welded. CNC-machined mounting holes for motors, linear rails and mating surfaces after welding.

Technical Specifications

Manufacturing Process

Flatness inspection, rust-proof painting

Recommended Materials

SS400 mild steel is the primary material for machine frames due to high mechanical strength and reasonable cost. SGCC for lighter frames. Stainless SUS 304 for special environments.

Industry Applications

Frequently Asked Questions

How much does machine frame fabrication cost?

Price depends on size, steel weight and fabrication complexity. Standard frame (1000×800×600mm, SS400 5mm) from $80–200 each. Send drawings for quote.

How long does machine frame fabrication take?

7–15 business days depending on size and quantity. Rush service in 5 days. Large orders need 20–30 days.