Custom Solar Mounting Brackets — Quick Install, Long-Lasting

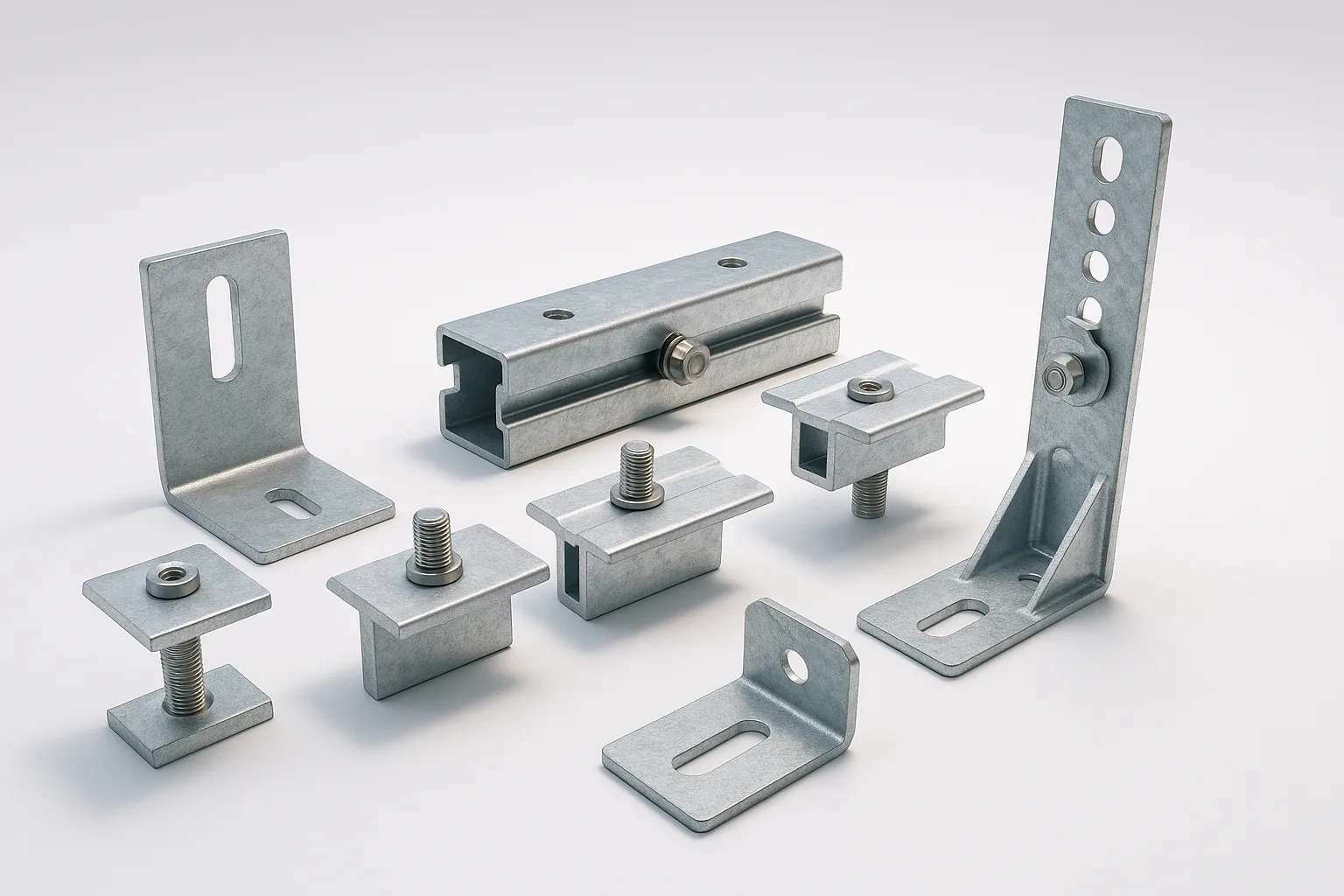

Mounting brackets and hardware for solar panel installations. Aluminum 6061, galvanized steel, modular design for any rooftop or ground-mount system.

What are solar mounting brackets?

Solar mounting brackets connect solar panels to support frames or directly to rooftops. Types include: L-brackets, mid clamps, end clamps, roof feet and adjustable tilt brackets.

Solar brackets must withstand wind load tension/compression, resist outdoor corrosion and last 25+ years. Common materials: anodized aluminum 6061 (lightweight, durable) or galvanized SGCC steel (affordable, high load capacity).

Technical Specifications

Manufacturing Process

Drill and tap standard bolt holes

Anodize aluminum or galvanized finish

Recommended Materials

Anodized aluminum 6061 is the standard for solar brackets due to its lightweight and superior corrosion resistance. Galvanized SGCC for heavy-load brackets. Hot-dip galvanized SS400 for ground-mount systems.

Industry Applications

Frequently Asked Questions

Aluminum or steel solar brackets — which is better?

Anodized aluminum is 65% lighter, better corrosion resistance, 30+ year life — ideal for rooftops. Galvanized steel has higher load capacity and lower cost — suitable for ground-mount and industrial systems.

What is the minimum order for solar brackets?

No minimum order. We accept from 10 pieces (prototyping) to tens of thousands (large projects). Laser cutting is ideal for both prototyping and volume production.