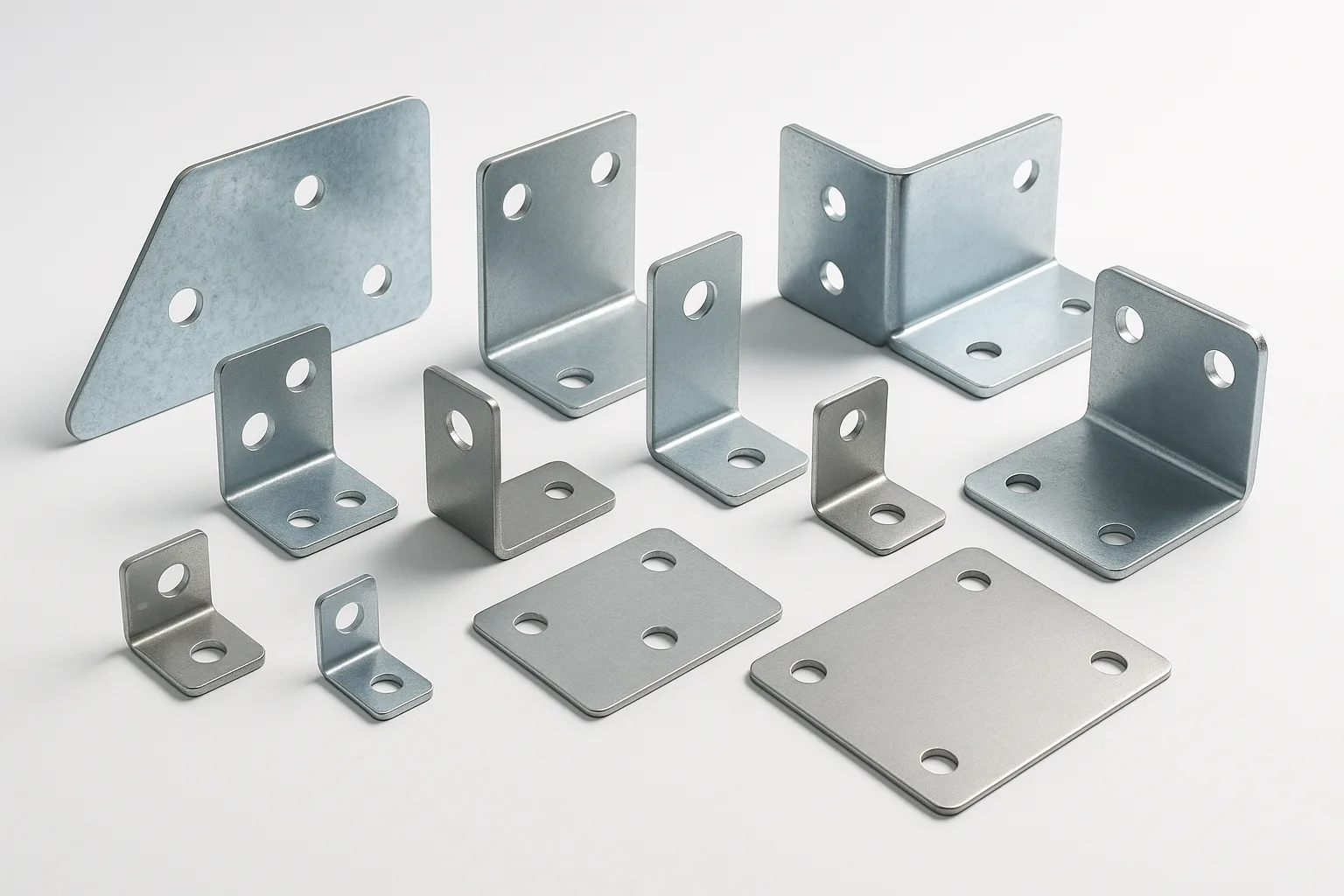

Custom Metal Brackets & Mounting Hardware — Precise & Fast

Custom brackets, mounts and angle pieces from technical drawings. Diverse materials, tight tolerances, suitable for machinery assembly and structural applications.

What are metal brackets?

Brackets are metal parts used to attach, connect and support various components in machinery, steel structures, electrical cabinets and electronics. Common shapes: L, U, Z or custom.

Brackets require tight tolerances (±0.1mm) for precise assembly. Laser cutting combined with CNC bending enables complex brackets at lower cost than CNC milling.

Technical Specifications

Manufacturing Process

Drill and tap mounting holes (if needed)

Tolerance inspection and surface treatment

Recommended Materials

SS400 mild steel is the most economical for brackets. SUS 304 for corrosion resistance. Aluminum 5052/6061 when weight matters. SGCC for electrical cabinet brackets.

Industry Applications

Frequently Asked Questions

What is the smallest bracket you can fabricate?

We can cut parts as small as 5×5mm. However, the optimal size for laser cutting + bending is 20×20mm and above.

Can you produce brackets in large volumes?

Yes. Laser cutting can produce thousands of brackets per day. Higher quantities mean lower unit prices — contact us for volume pricing.