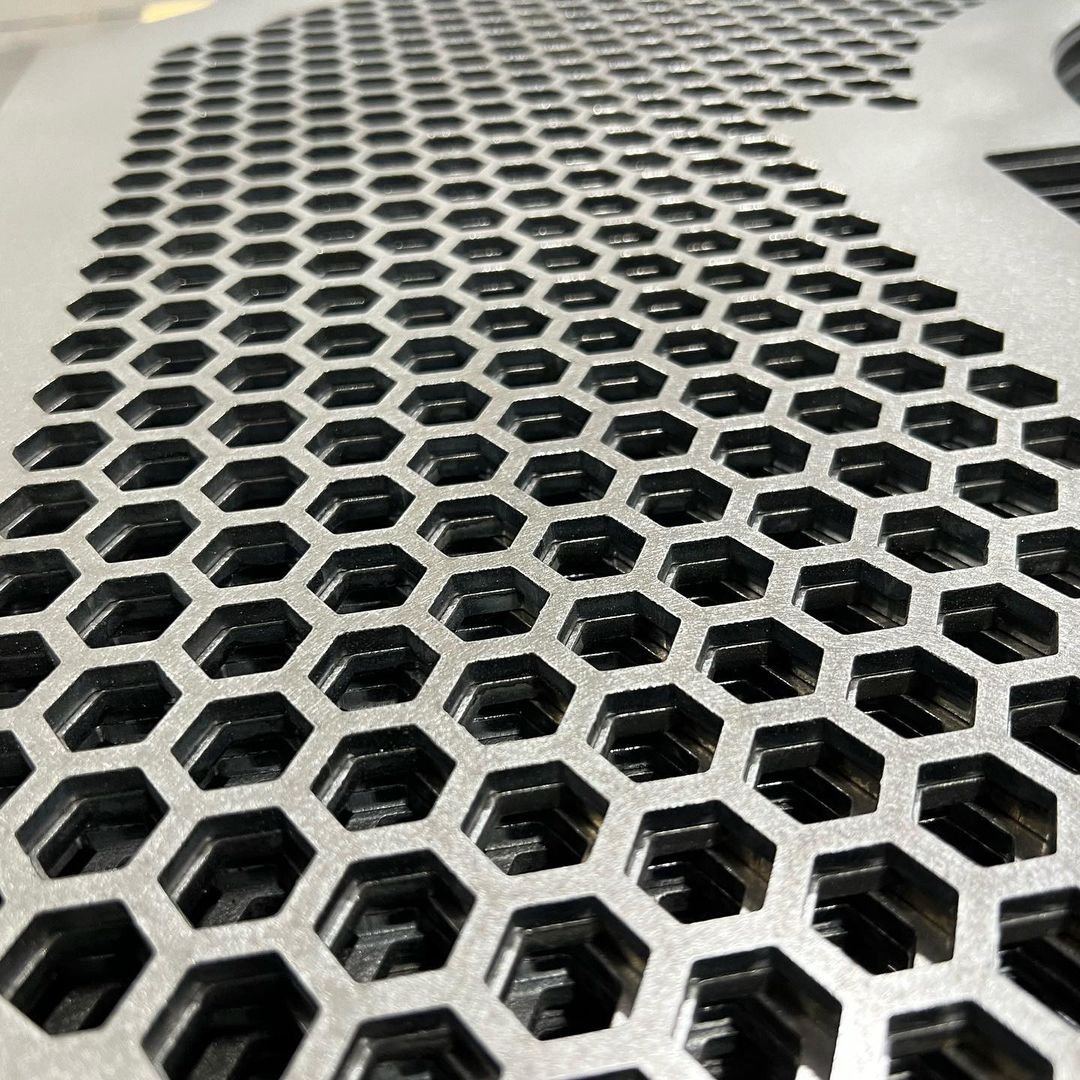

Sheet Metal Powder Coating Service.

Tuan Thinh’s Powder Coating Service offers a durable and attractive finish for all your metal parts. Our powder coating process provides a uniform, long-lasting coat that not only enhances the appearance of your parts but also adds a layer of protection against wear and corrosion. Perfect for both functional and aesthetic purposes.

Choosing Gloss & Texture

It is important to highlight that the standards for gloss levels in use are not uniform across all service providers. There is always a gloss level in numerical form next to the description that may vary quite a lot between different suppliers. So we would advise to always look at that number rather than the description.

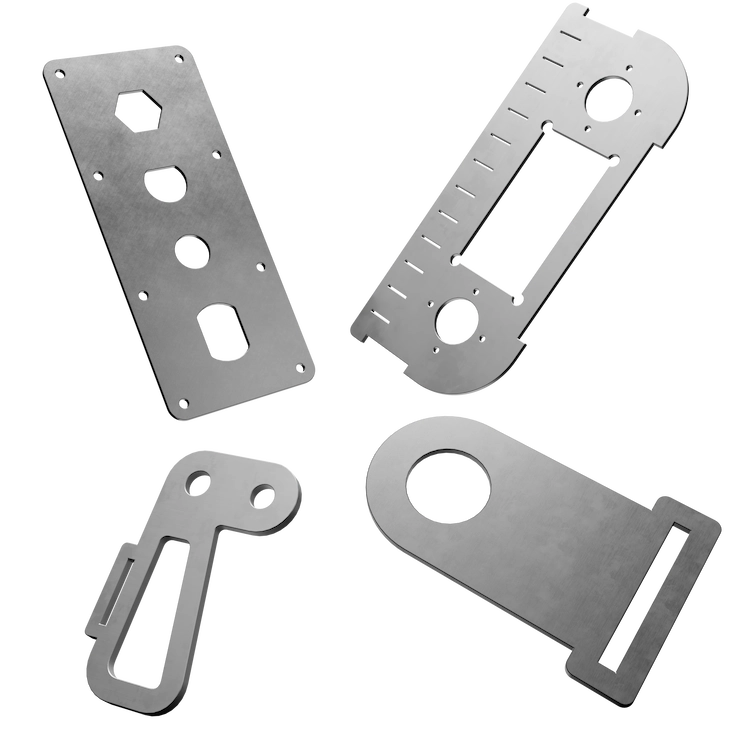

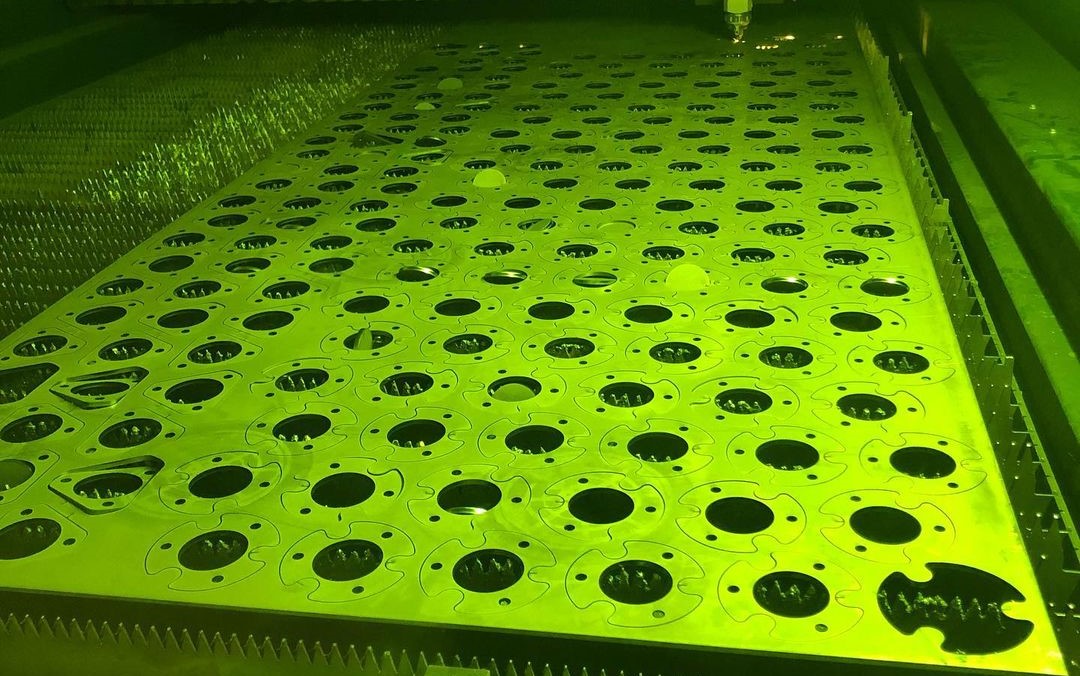

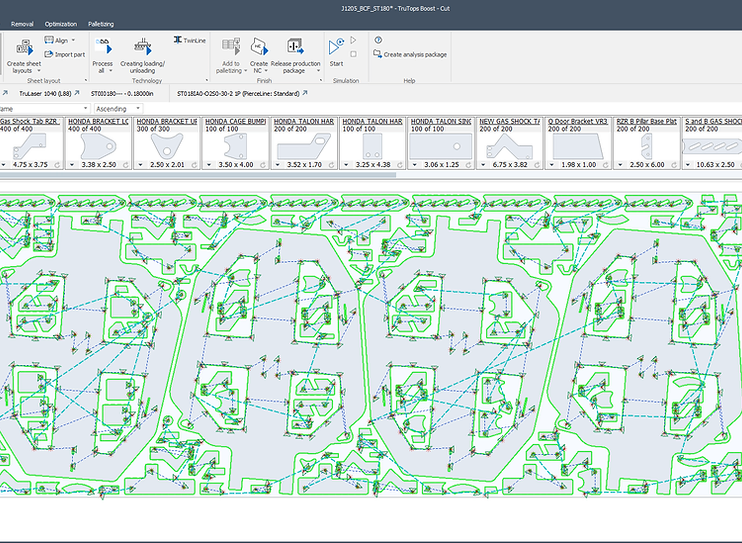

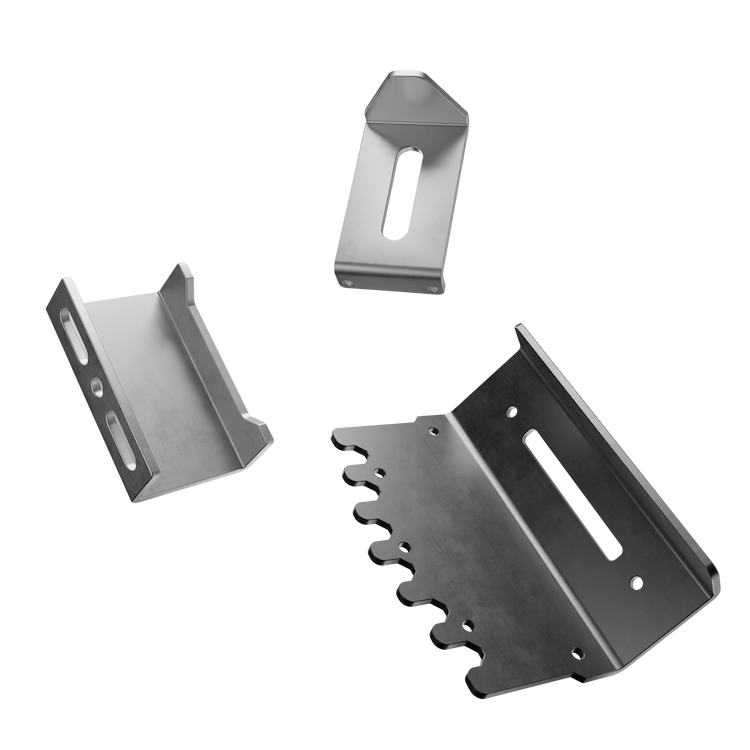

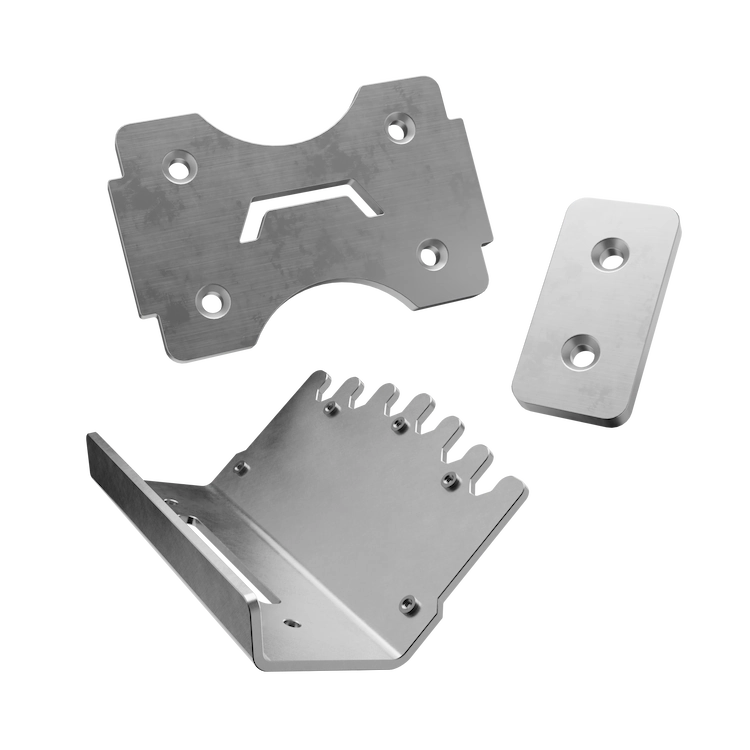

High Precision Laser Cutting.

At Tuan Thinh, we believe in serving all your laser cutting needs, big or small. With no minimum order requirements, we’re here to support a single prototype or a large production run. We’re committed to providing the same high level of quality on all order sizes.

Smart Technology

Intelligent software and talented programmers ensure your files are accurate and optimal.

Throughout the entire cutting process materials are monitored for material changes and potential errors. This ensures consistent accurate parts every time despite material variations.

Intelligent software nesting allows for material optimization.

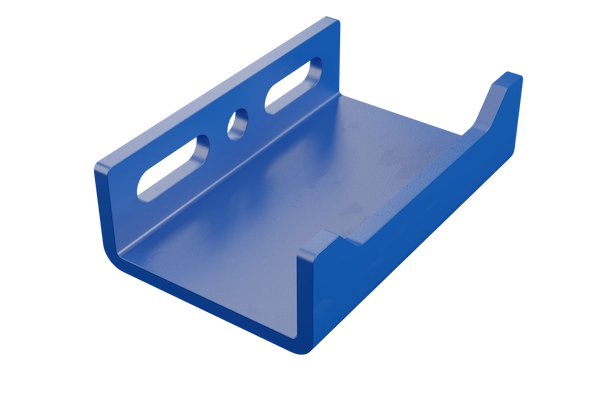

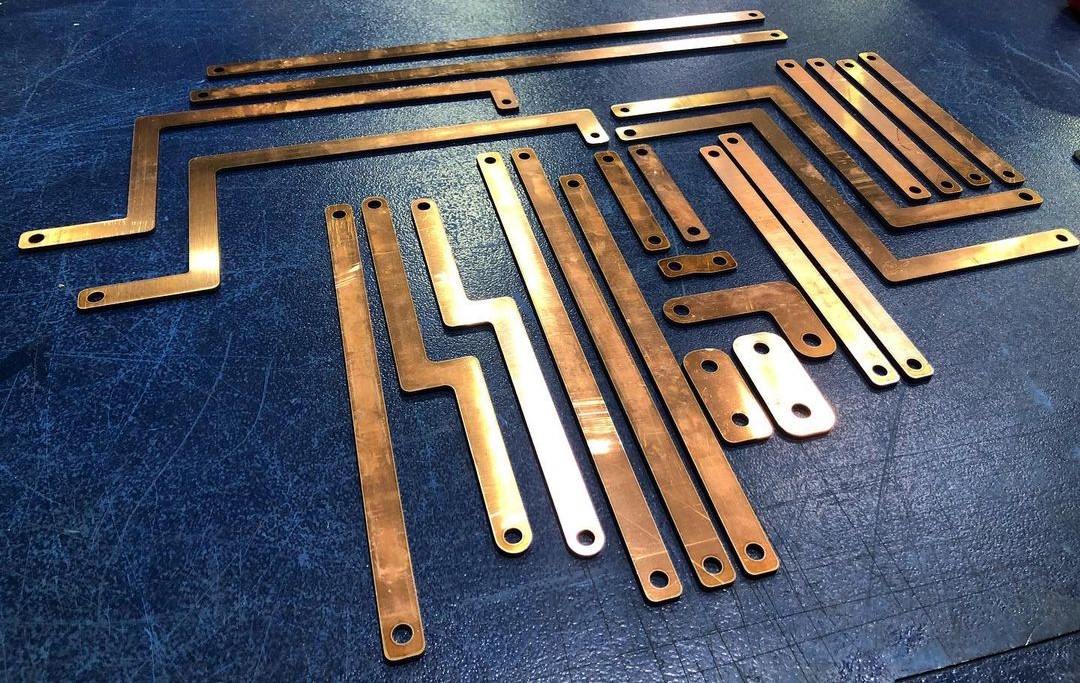

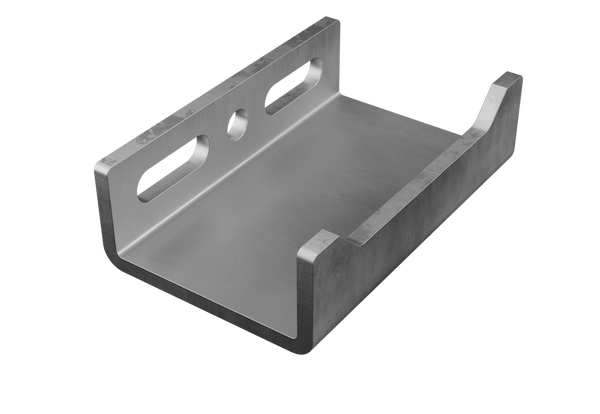

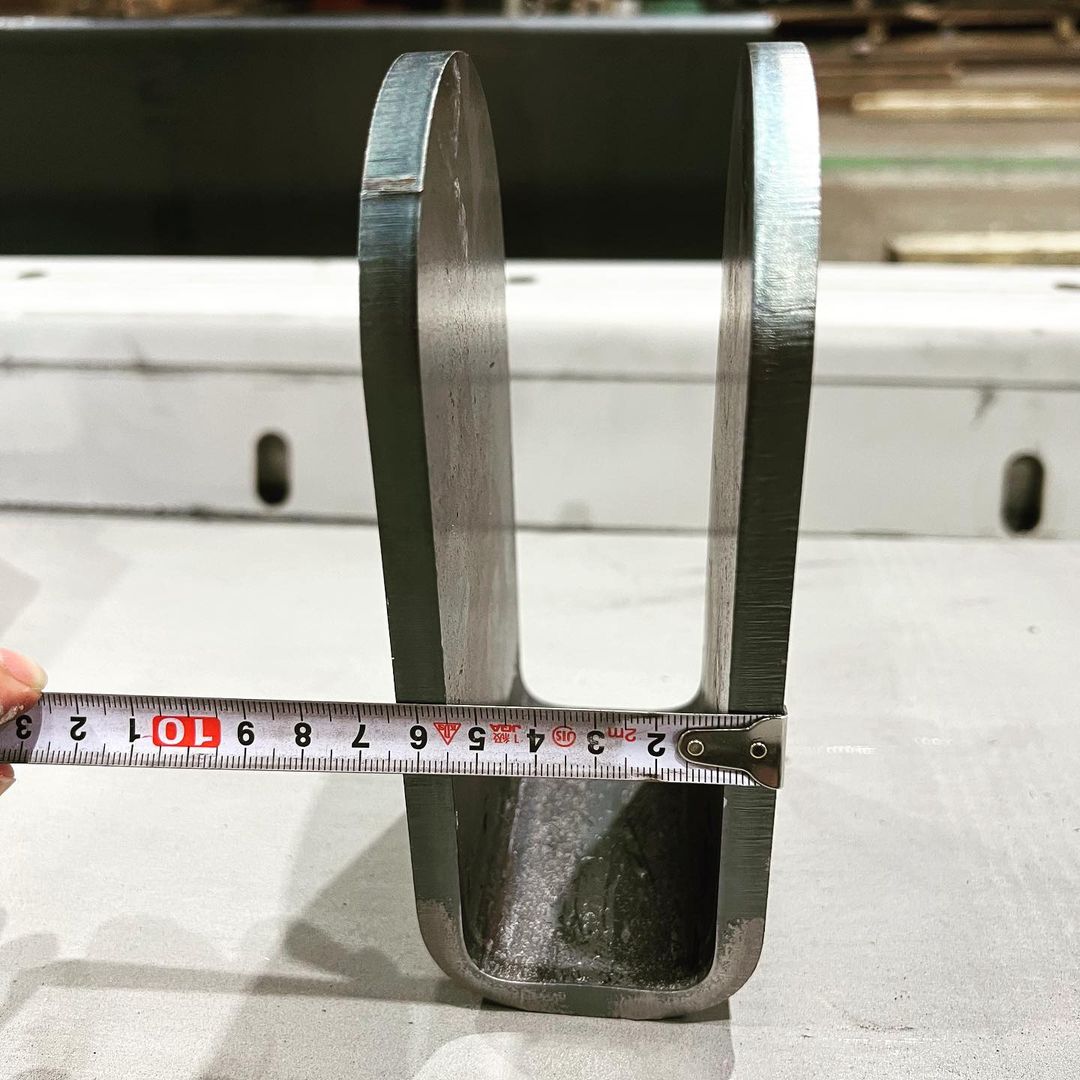

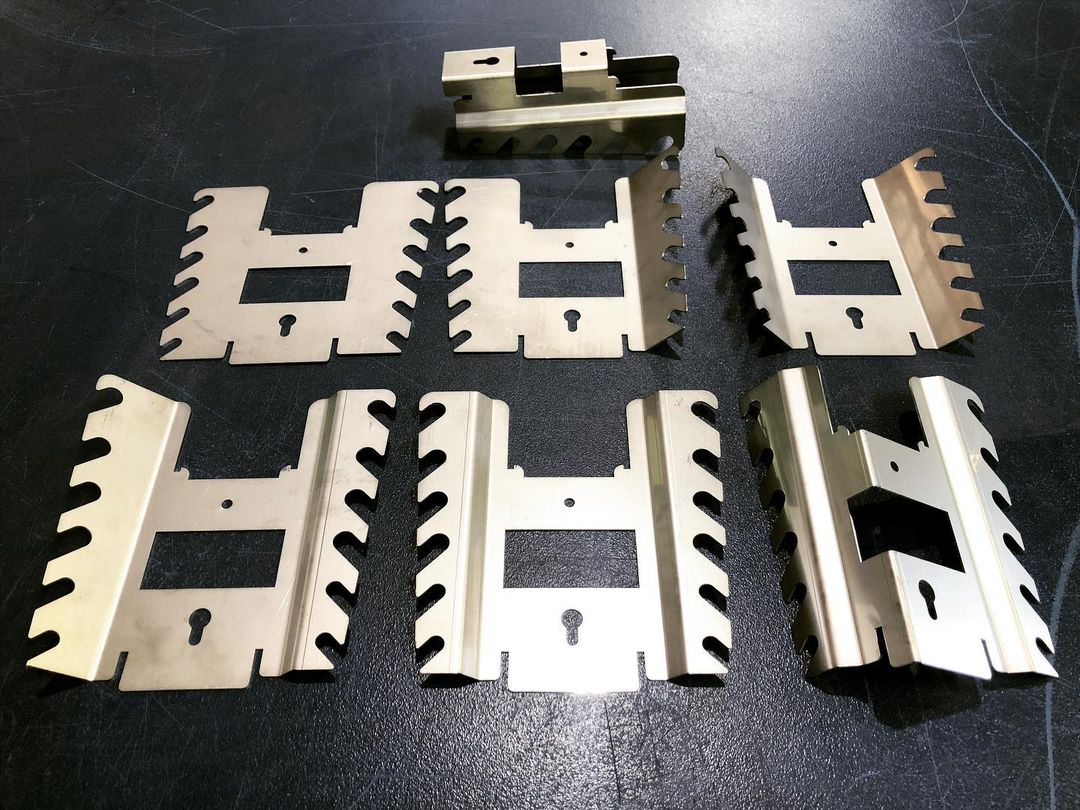

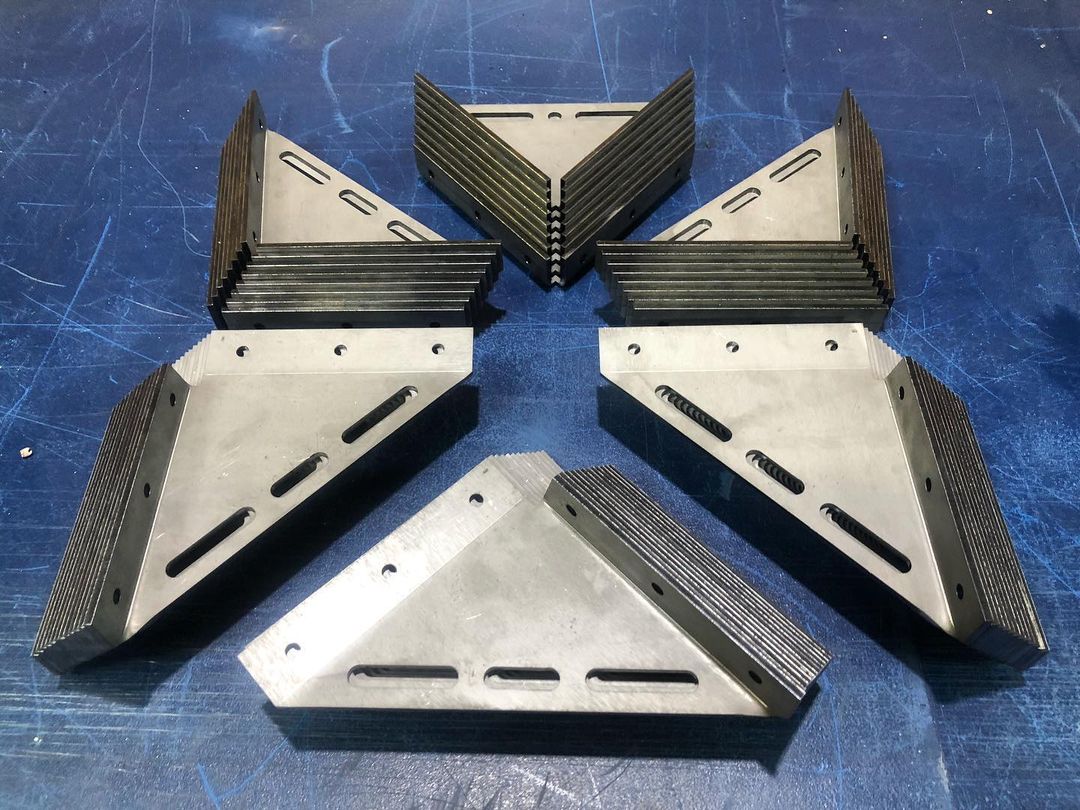

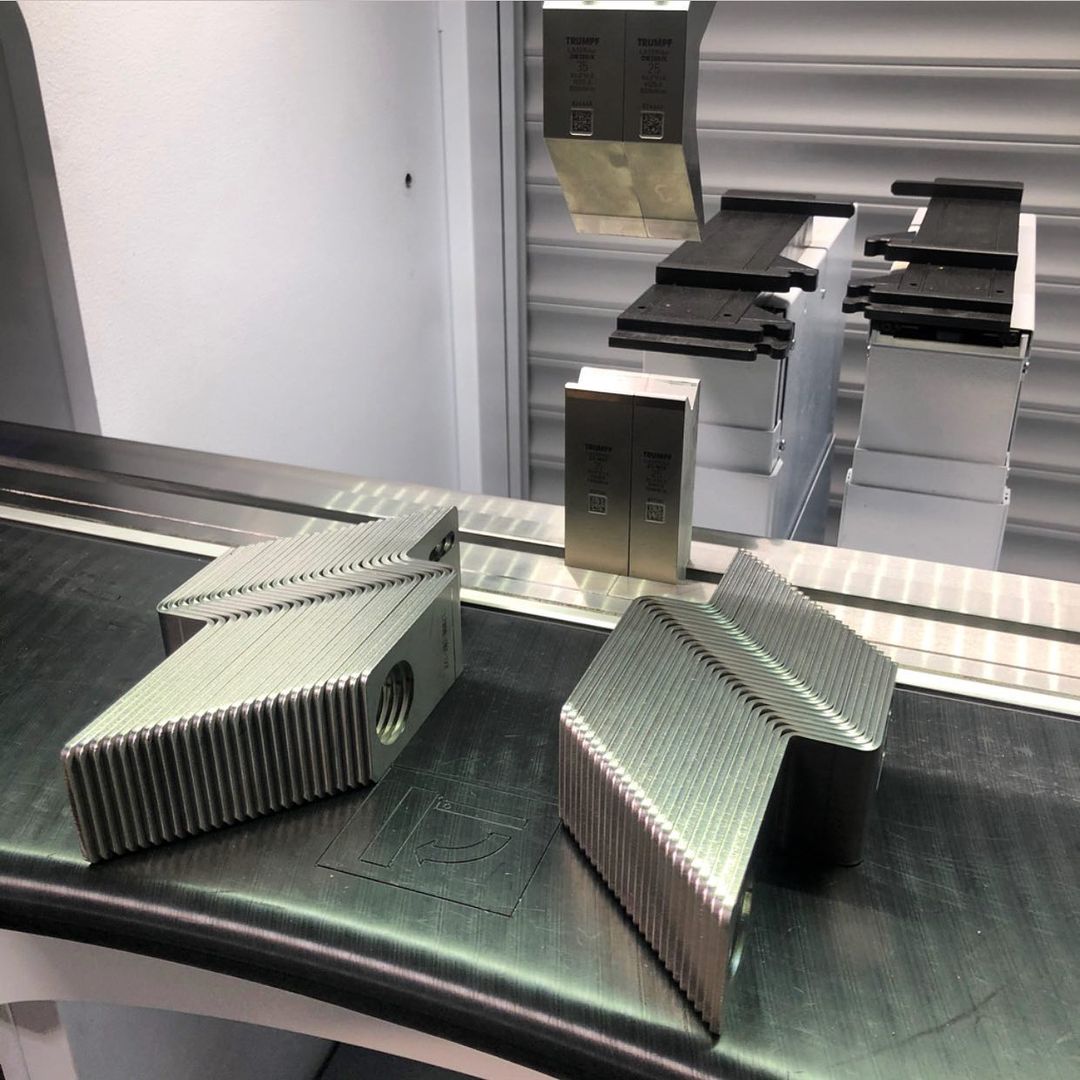

Precision Sheet Metal Bending.

Precision isn’t just a goal, it’s a guarantee. Our advanced sheet metal bending service combines cutting-edge CNC technology with skilled expertise to deliver bends that meet your exact specifications.

Smart Technology

Intelligent software and talented programmers ensure your files are accurate and optimal.

Throughout the entire bending process materials are monitored for material changes and potential errors. This ensures consistent accurate parts every time despite material variations.

Intelligent software bending allows for precision and flexibility.

Precision Countersinking.

Our countersinking process ensures that every hole is perfectly shaped and sized for its intended hardware. This precision not only enhances the aesthetic appeal of your parts but also significantly improves their functionality and fit.

| Name | Units | Hole Size | Outer Diameter |

|---|---|---|---|

| #4×82º CS | in | 0.129″ | 0.255″ |

| #6×82º CS | in | 0.150″ | 0.307″ |

| #8×82º CS | in | 0.177″ | 0.359″ |

| #10×82º CS | in | 0.201″ | 0.411″ |

| 1/4×82º CS | in | 0.266″ | 0.531″ |

| M2x90º CS | mm | 0.095″ | 0.173″ |

| M3x90º CS | mm | 0.134″ | 0.265″ |

| M4x90º CS | mm | 0.177″ | 0.353″ |

| M5x90º CS | mm | 0.217″ | 0.441″ |

| M6x90º CS | mm | 0.260″ | 0.529″ |

Sheet Metal Hardware Service.

Hardware, specifically PEM nuts, are a significant component in sheet metal fabrication, especially when it comes to enhancing the assembly and robustness of sheet metal parts. PEM nuts are a type of self-clinching fastener that, when installed into a pre-cut hole and subjected to sufficient force, clinches into the sheet metal, creating a permanent and strong thread in thin metal sheets.

| Name | Units | Hole Size | Outer Diameter |

|---|---|---|---|

| #4-40 Nut | in | 0.166″ | 0.250″ |

| #6-32 Nut | in | 0.188″ | 0.280″ |

| #8-32 Nut | in | 0.213″ | 0.310″ |

| #10-32 Nut | in | 0.250″ | 0.340″ |

| #10-24 Nut | in | 0.250″ | 0.340″ |

| 1/4-20 Nut | in | 0.344″ | 0.440″ |

| 1/4-28 Nut | in | 0.344″ | 0.440″ |

| M3x0.5 Nut | mm | 0.166″ | 0.250″ |

| M4x0.7 Nut | mm | 0.213″ | 0.310″ |

| M5x0.8 Nut | mm | 0.250″ | 0.340″ |

| M6x1.0 Nut | mm | 0.344″ | 0.440″ |

| M8x1.25 Nut | mm | 0.414″ | 0.500″ |

Sheet Metal Tapping Service.

Tapping in sheet metal fabrication is crucial for constructing a broad range of products, as it facilitates the assembly and disassembly of components. The process grants design flexibility and enables the creation of durable, robust structures. Whether it’s an electronics enclosure, a machine component, or a piece of furniture, if it involves joining sheet metal parts, tapping likely plays a vital role.

| Name | Units | Hole Size | Outer Diameter |

|---|---|---|---|

| #4×82º CS | in | 0.129″ | 0.255″ |

| #6×82º CS | in | 0.150″ | 0.307″ |

| #8×82º CS | in | 0.177″ | 0.359″ |

| #10×82º CS | in | 0.201″ | 0.411″ |

| 1/4×82º CS | in | 0.266″ | 0.531″ |

| M2x90º CS | mm | 0.095″ | 0.173″ |

| M3x90º CS | mm | 0.134″ | 0.265″ |

| M4x90º CS | mm | 0.177″ | 0.353″ |

| M5x90º CS | mm | 0.217″ | 0.441″ |

| M6x90º CS | mm | 0.260″ | 0.529″ |

Send Us A Message